Understanding Electrical Resistance : Part 2

Continued from Electrical Resistance - Part 1...

Conductance

Electricity is a study that is frequently explained in terms of opposites. The term that is opposite of resistance is Conductance. Conductance is the ability of a material to pass electrons.

The factors that affect the magnitude of resistance are exactly the same for conductance, but they affect conductance in the opposite manner. Therefore, conductance is directly proportional to area, and inversely proportional to the length of the material.

The temperature of the material is definitely a factor, but assuming a constant temperature, the conductance of a material can be calculated.

The unit of conductance is the MHO, which is ohm spelled backwards. Another official term for mho is SIEMENS.

Whereas the symbol used to represent resistance (R) is the Greek letter omega (Ω), the symbol used to represent conductance (G) is (S).

The relationship that exists between resistance (R) and conductance (G) is a reciprocal one. A reciprocal of a number is one divided by that number. In terms of resistance and conductance: R=1/G and G=1/R

Electrical Resistors

Electrical components often have several properties. One property that every electrical component has is the property of Resistance. At times, the effects of resistance within an electrical component will be undesirable. However, at other times the resistance property of electrical components is used as a means to manipulate and control the electron current flow at specific locations within the electrical application or circuit.

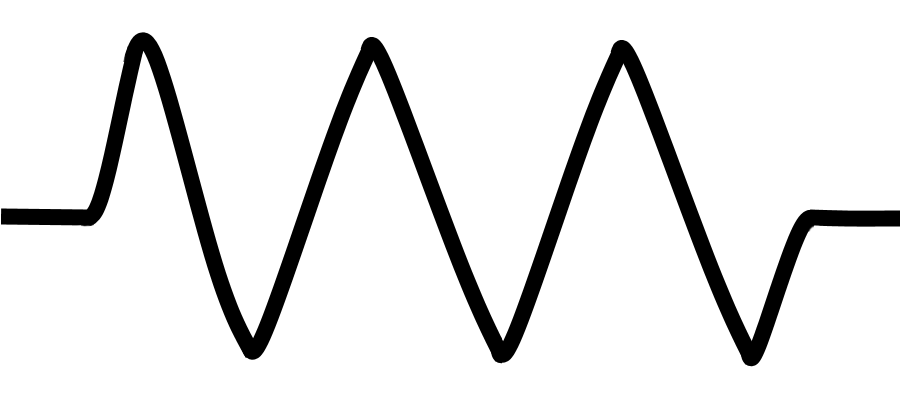

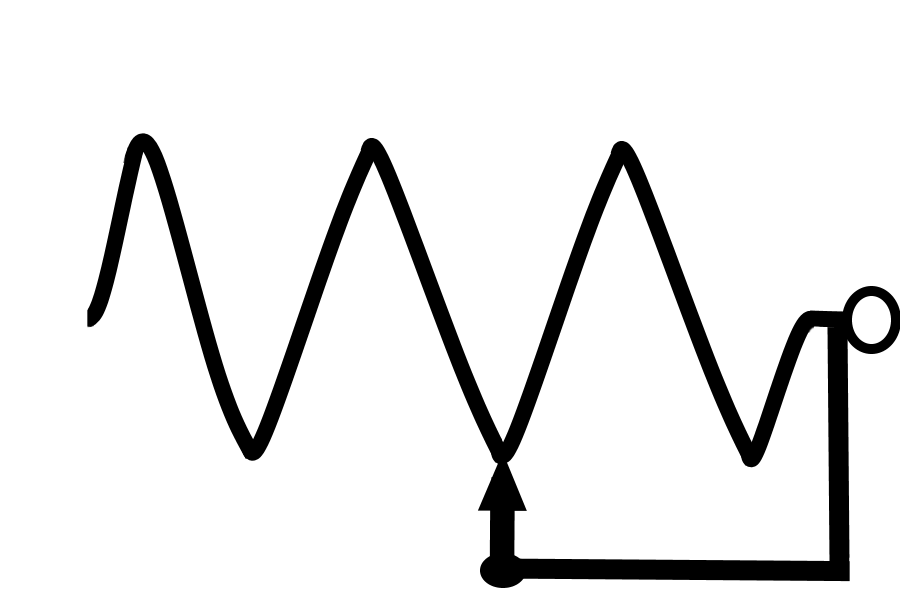

Resistors are components manufactured to posses specific values of resistance. They are manufactured in many types and sizes. When drawn using its schematic representation, a resistor is often shown as a series of jagged lines.

Composition of Resistors

One of the most common types of resistors is the molded composition, usually referred to as the carbon resistor. These resistors are manufactured in a variety of sizes and shapes.

The chemical composition of the resistor determines its ohmic value and is accurately controlled by the manufacturer in the development process. They are made in ohmic values that range from one ohm to millions of ohms.

The physical size of a resistor is related to its overall wattage rating. A resistors wattage rating is used to rate the ability of the resistor to dissipate heat that is produced from electrons passing through the resistor, while being influence by the resistance action of the resistor (that is, the energy of the electron is converted into heat as a direct opposition to the resistors resistance to electron current flow).

As the name implies, Carbon resistors have as their principal ingredient the element carbon. In the manufacture of carbon resistors, fillers or binders are added to the carbon to obtain various resistor values. Examples of these fillers are clay, bakelite, rubber, and talc. These fillers are doping agents and cause the overall conduction characteristics to change.

Carbon resistors are the most common resistors found in use today because they are easy to manufacture, inexpensive, and they have a tolerance that is adequate for most electrical and electronic applications. Their prime disadvantage is that they have a tendency to change value as they age. Another disadvantage of carbon resistors is their limited power handling capabilities.

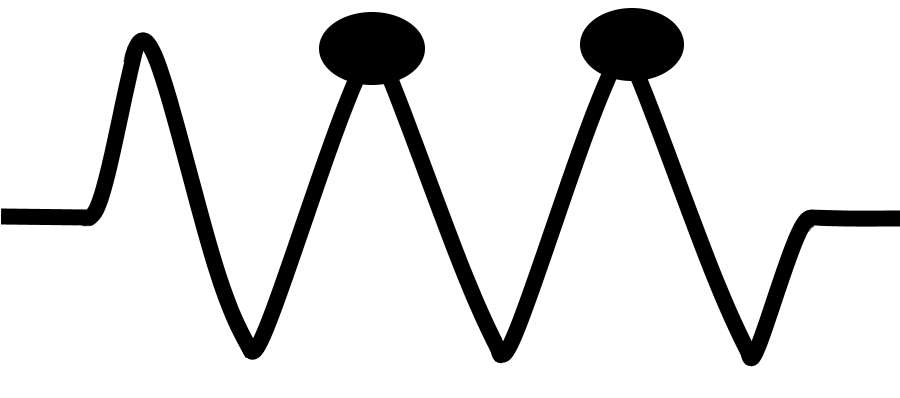

The disadvantages of carbon resistors can be overcome by the use of wirewound resistors. Wirewound resistors have very accurate values and posses a higher current handling capability than carbon resistors. The material that is frequently used to manufacture wirewound resistors is German silver, which is composed of copper, nickel, and zinc. The qualities and quantities of these elements present in the wire determine the resistivity of the wire.

|

|

|

The resistivity of the wire is the measure or ability of the wire to resist current. Usually the percentage of nickel in the wire determines the resistivity.

One disadvantage of the wirewound resistor is that it takes a large amount of wire to manufacturer a resistor of high ohmic value, thereby increasing the cost.

A variation of the wirewound resistor provides an exposed surface to the resistance wire on one side. An adjustable tap is attached to this side. Such resistors, sometimes with two or more adjustable taps, are used as voltage dividers in power supplies and other applications where a specific voltage is desired to be tapped off.

Fixed and Variable Resistors

There are two kinds of resistors, Fixed and Variable.

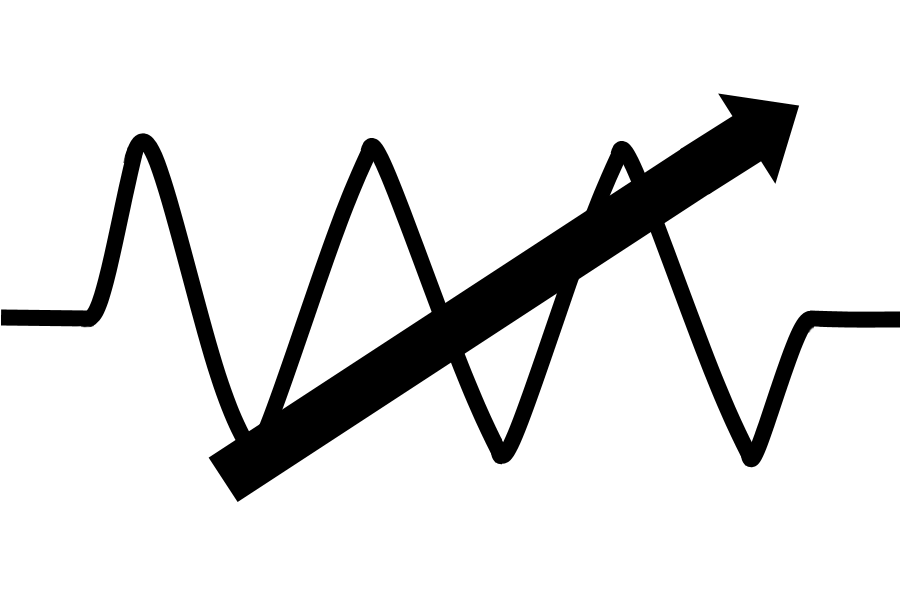

The fixed resistor will have one value and will never change (other than through temperature, age, etc). The tapped resistor has one or more fixed taps and makes more than one resistance value available, even though it is still considered to be a fixed resistor. For variable resistors, the sliding contact resistor (also known as an adjustable wirewound resistor) has an adjustable collar that can be moved to tap off any resistance within the ohmic value range of the resistor.

There are two types of variable resistors, Potentiometer and Rheostat.

|

|

|

|

|

|

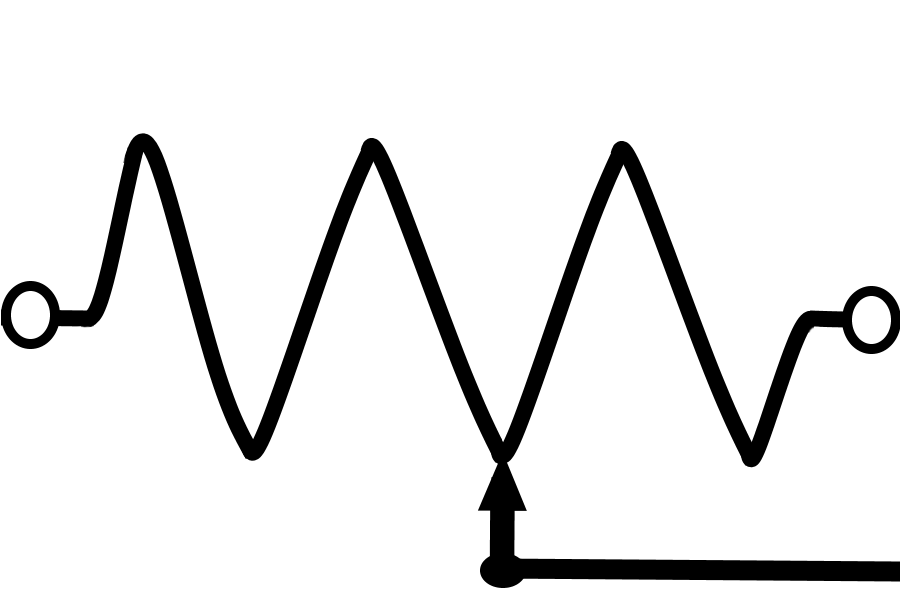

An example of the potentiometer is the volume control knob on a portable radio. An example of the rheostat is the dimmer control for the dash lights in most automobiles.

The slight difference that exists between them is that the rheostats usually have two connections (one fixed and the other moveable). Any variable resistor can properly be called a rheostat. The potentiometer always has three connections (two fixed and one moveable).

Generally, the rheostat has a limited range of resistance values but it has high current-handling capabilities. The potentiometer has a wide range of values, but it usually has limited current-handling capabilities. Potentiometers are always connected as voltage dividers.

Wattage Rating

When a current is passed through a resistor, heat is developed within the resistor. The resistor must be capable of dissipating this heat into the surrounding air, otherwise the temperature of the resistor will rise to a point that causes a change in resistance, or possibly causes the resistor itself to burn out and no longer function.

The ability of the resistor to dissipate heat depends upon the design of the resistor itself. This ability to dissipate heat depends on the amount of surface area which is exposed to the air. A resistor designed to dissipate a large amount of heat must therefore have a large physical size.

The heat dissipating capability of a resistor is measured in Watts.

Some of the more common wattage ratings of carbon resistors are: 1/8, 1/4, 1/2, 1, and 2 watts. In some newer state-of-the-art circuits in use today (such as with advanced computerized cellphones), much smaller wattage resistors are used. The higher the wattage rating of the resistor the larger its physical size. Therefore to meet the physical requirement size demands of cellphones, the cellphones circuits were desired to use less watts and therefore smaller resistors.

Resistors that dissipate very large amounts of power (watts) are usually wirewound resistors. Wirewound resistors with wattage ratings up to and more than 50 watts are not uncommon.

Continue with Electrical Resistance - Part 3