Understanding Batteries : Part 1

In this blog post I would like to explain the overall basics of what Batteries are, how they work, and how they are made, as I currently understand it to be.

Batteries are widely used as sources of direct-current (DC) electrical energy. Some batteries are small, light weight, and can easily be portable, whereas other batteries may be so large and so heavy that it is impractical for them to be portable. In some instances, batteries are used as the primary source of power for an application, whereas in other applications the batteries may be used as secondary or backup power used only when primary power is lost.

Battery Components

In respect to batteries, a cell is a device that transforms chemical energy into electrical energy. The simplest type of cell is known as a galvanic or voltaic cell.

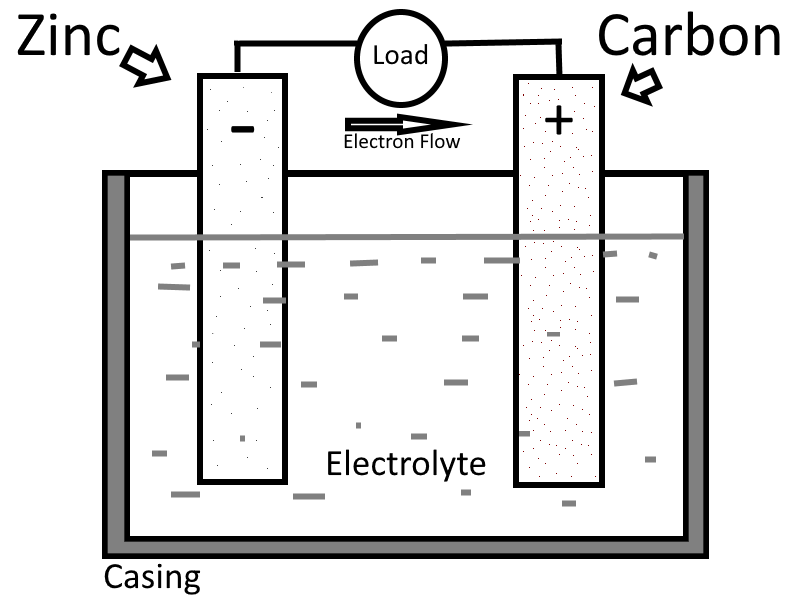

The galvanic or voltaic cell consists of a piece of carbon and a piece of zinc suspended in a jar that contains a solution of water and sulfuric acid, called the electrolyte. The cell is the fundamental unit of the battery. A simple cell consists of two electrodes placed in a container that holds the electrolyte. In some cells the container acts as one of the electrodes, and in this case is acted upon by the electrolyte. The electrodes are the conductors by which the current leaves or returns to the electrolyte. In the simple cell, the electrodes are the carbon and zinc strips that are placed in the electrolyte. In a dry cell, the electrodes are the carbon rod in the center and the zinc container in which the cell is assembled.

The electrolyte is the solution that acts upon the electrodes. The electrolyte, which provides a path for electron flow, may be a salt, an acid, or an alkaline solution. In the simple galvanic cell the electrolyte is in a liquid form. In the dry cell the electrolyte is usually a paste. The container, which could be made out of various different materials, provides a means of holding the electrolyte and keeping it contained within. The container is also used to mount and secure the electrodes. In the voltaic cell the container must be constructed of a material that will not be acted upon by the electrolyte.

Primary and Secondary Type Cells

A primary cell is one in which the chemical action eats away one of the electrodes, usually the negative electrode. When this happens, the electrode must be replaced or the cell must be discarded. In the galvanic-type cell, the zinc electrode and the liquid electrolyte are usually replaced when this happens. In the case of the dry cell, it is usually cheaper to just buy a new cell. Examples of primary cell batteries are common non-rechargeable AA, AAA, and 9V batteries.

A secondary cell is one in which the electrodes and the electrolyte are altered by the chemical action that takes place when the cell delivers current. These cells may be restored to their original condition by forcing an electric current through them in the direction opposite to that of normal discharge of the cell. A car or automobile battery is a common example of the secondary cell, since the vehicles alternator can recharge the battery by forcing reverse current back into the battery to restore the battery's electrode.

ElectroChemical Action

A cell is a device that converts chemical energy into electrical energy. This process of converting chemical energy into electrical energy is called ElectroChemical Action.

If a separate device or circuit that consumes electrical power (a load) is externally connected to the electrodes of a cell, then electrons will flow under the influence of a difference in potential across the electrodes from the Cathode (negative electrode), through the external conductor and device, and then back to the Anode (positive electrode).

The voltage across the electrodes depends upon the materials that the electrodes are made up of and the composition of the electrolyte solution that the electrodes are contained within. The amount of current that a cell delivers depends upon the resistance of the entire circuit, including that of the cell itself. The internal resistance of the cell depends upon the size of the electrodes, the distance between the electrodes in the electrolyte, and the resistance of the electrolyte solution. The larger the electrodes and the closer together they are in the electrolyte (without touching), the lower the internal resistance of the cell and the more current the cell is capable of supplying to the load.

Primary Cell Chemistry (Non-Rechargeable Battery)

Lets assume that we have a brand new primary cell that is composed of carbon and zinc electrodes that are contained in an electrolyte diluted solution of sulfuric acid and water. When a current flows through this primary cell, the following chemical reaction takes place.

The current flow through the load is the movement of electrons from the negative electrode of the cell (zinc) and to the positive electrode (carbon). This causes fewer electrons in the zinc and an excess of electrons in the carbon. The hydrogen ions from the sulfuric acid are being attracted to the carbon electrode. Since the hydrogen ions are positively charged they are attracted to the negative charge on the carbon electrode. This negative charge is caused by the excess of electrons. The zinc electrode has a positive charge because it has lost electrons to the carbon electrode. This positive charge attracts the negative ions from the sulfuric acid. The negative ions combine with the zinc to form zinc sulfate. This action causes the zinc electrode to be eaten away. Zinc sulfate is a grayish-white substance that is sometimes seen on the battery posts of a car or an automobile battery.

The process of the zinc being eaten away and the sulfuric acid changing to hydrogen and zinc sulfate is the cause of the cell discharging. When the zinc is used up, the voltage of the cell is reduced to zero.

The reason why the zinc electrode is labeled negative and the carbon electrode is labeled positive on the battery, is because they represent what the current flow outside of the cell is from negative to positive.

The zinc combines with the sulfuric acid to form zinc sulfate and hydrogen. The zinc sulfate dissolves in the electrolyte (sulfuric acid and water) and the hydrogen appears as gas bubbles around the carbon electrode. As current continues to flow, the zinc gradually dissolves and the solution changes to zinc sulfate and water. The carbon electrode does not enter into the chemical changes taking place, but instead it simply provides a return path for the electron current flow.

Secondary Cell Chemistry (Rechargeable Battery)

The main difference (only difference) between a primary and a secondary cell is that a secondary cell can be recharged, whereas a primary cell cannot. The reason why a secondary cell can be recharged is due to it being made up of different types of materials that simply allow it.

For example, instead of being made with zinc and carbon electrodes like a primary cell, a secondary cell may use sponge lead as the cathode and lead peroxide as the anode electrodes. This is known as a lead-acid type cell. There may be other types of materials used to form different types of secondary cells, however the overall basic principal and internal chemical action is essentially the same.

In this secondary cell example, the cathode is pure sponge lead, and the anode is pure lead peroxide, and the electrolyte is again just a mixture of sulfuric acid and water.

For discharging the cell, a load is connected between the cathode and anode, allowing current to flow from the negative to the positive. This current flow is similar to the current flow of a primary cell, but with the following exceptions.

In the primary cell, the zinc cathode was eaten away by the sulfuric acid. In the secondary cell, the sponge-like construction of the cathode retains the lead sulfate formed by the chemical action of the sulfuric acid and the lead. In the primary cell the carbon anode was not chemically acted upon by the sulfuric acid. In the secondary cell the lead peroxide anode is chemically changed to lead sulfate by the sulfuric acid.

When the secondary cell is fully discharged, the anode and cathode retain some lead peroxide and sponge lead but the amounts of lead sulfate in each is maximum. The electrolyte has a minimum amount of sulfuric acid. With this condition no further chemical action can take place within the cell, and the cell will no longer produce current flow until it has been recharged.

Recharging is the process of reversing the chemical action that occurs as the cell discharges. To recharge the cell, an external voltage source (such as a generator) must be connected to the cells electrodes. The negative terminal of the voltage source is connected to the cathode of the cell and the positive terminal of the voltage source is connected to the anode of the cell. With this arrangement the lead sulfate is chemically changed back to sponge lead in the cathode, lead peroxide in the anode, and sulfuric acid in the electrolyte. After all of the lead sulfate is chemically changed back, the cell is fully charged (or fully recharged). Once the cell has been charged, the discharge-charge cycle may be repeated.

Polarization

The chemical action that occurs in the cell while the current is flowing causes hydrogen bubbles to form on the surface of the anode. This action is called Polarization.

Some hydrogen bubbles rise to the surface of the electrolyte and escape into the air, while some remain on the surface of the anode. If enough bubbles remain around the anode, the bubbles form a barrier that increases internal resistance. When the internal resistance of the cell increases, the output current is decreased and the voltage of the cell also decreases.

A cell that is heavily polarized has no useful output. There are several methods to prevent polarization, as well as to depolarize the cell.

One method uses a vent on the cell to permit the hydrogen to escape out of the cell and into the surrounding air. However, this method causes the vented hydrogen to now no long be available for it to reform back into the electrolyte during the charging process. This might be overcome to some degree by adding additional water to the electrolyte at the time the battery is recharged. Also, the vented gas itself is considered to be poisonous, and therefore it must be adequately vented away from the area for safety reasons.

A second method is to use materials inside the cell that are rich in oxygen, such as manganese dioxide, which supplies free oxygen to combine with the hydrogen and form water.

A third method is to use materials inside the cell that will absorb the hydrogen, such as calcium. The calcium releases hydrogen during the charging process.

Local Actions (Shelf Life)

When the external circuit (the load) is removed from the electrode terminals of the battery cell, the current ceases to flow, and theoretically all of the chemical actions within the cell stops. However, commercial zinc contains many impurities, such as iron, carbon, lead, and arsenic. These impurities form many small electrical cells within the zinc electrode, which causes current to flow between the zinc and its impurities. Therefore, the chemical action continues even though the cell itself is not connected to a load, which slowly drains the battery. This is known as Local Action, and it partly explains why a disconnected battery will still drain itself even when it is not in use.

Local action may be prevented (or minimized and reduced) by either using pure zinc (however this is simply not practical), by coating the zinc with mercury, or by adding a small percentage of mercury to the zinc during the manufacturing process. The treatment of the zinc with mercury is called amalgamating (mixing) the zinc.

Since mercury is many times heavier than an equal volume of water, small particles of impurities weighing less than mercury will float to the surface of the mercury. The removal of these impurities from the zinc prevents (or at least reduces and minimizes) local action.

The mercury is not readily acted upon by the acid. When the cell is delivering current to a load, the mercury continues to act on the impurities in the zinc. This causes the impurities to leave the surface of the zinc electrode and float to the surface of the mercury. This process greatly increases the storage life of the cell.

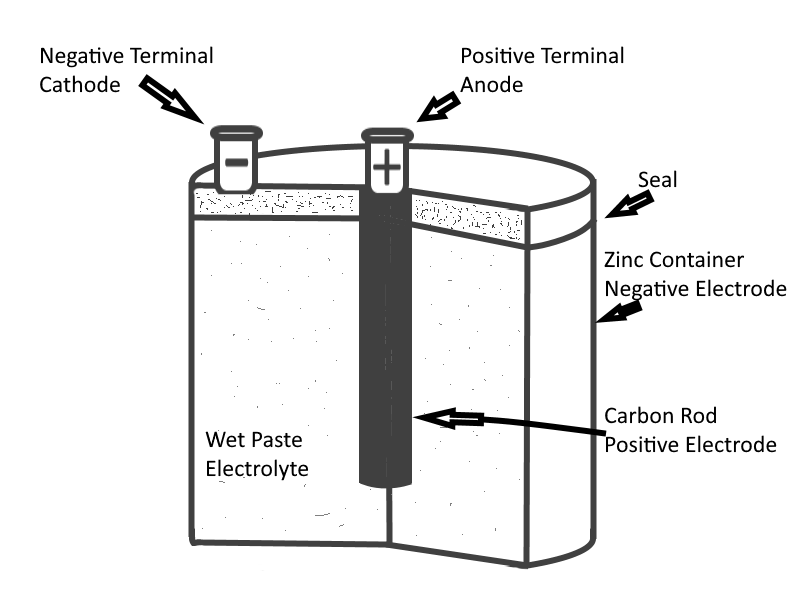

Primary Dry Cell

The dry cell is the most popular type of primary cell. It is ideal for simple applications where an inexpensive and noncritical source of electricity is all that is needed.

The dry cell is not actually dry, however. The electrolyte solution is not in a liquid state, but rather it is a moist paste. If it should ever actually dry out and become totally dry, then it would no longer be able to transform chemical energy to electrical energy.

The internal parts of a dry cell are located in a cylindrical zinc container. This zinc container serves as a negative electrode (cathode) of the cell. The container is lined with a nonconducting material, such as blotting paper, to separate the zinc from the electrolyte solution paste. A carbon electrode is located in the center, and it serves as the positive terminal (anode) of the battery cell. The electrolyte solution paste is a mixture of several substances, such as ammonium chloride, powdered coke, ground carbon, manganese dioxide, zinc chloride, graphite, and water.

This paste is packed into the space between the anode and the blotting paper, also serves to hold the anode securely in place in the center of the cell. When the paste is packed in the cell, a small space (a void of empty space) is left at the top to allow for expansion of the electrolyte solution (expansion that might be caused by the depolarization action). The cell is then sealed with a cardboard or plastic seal.

Since the zinc container is the cathode, it must be protected with some insulating material so that it is electrically isolated. Therefore, it is common practice for the manufacturer to enclose the cells in cardboard and metal containers.

The internal chemical reaction that occurs in a dry cell is basically the same as the reaction that occurs in the wet cell. The action of the water and the ammonium chloride in the paste, together with the zinc and carbon electrodes, produces the voltage of the cell. Manganese dioxide is added to reduce polarization when current flows and zinc chloride reduces local action when the cell is not being used.

A battery cell that is not being used, such as unused batteries that might be sitting on a storage shelf someplace, will gradually deteriorate because of slow internal chemical changes (local action). This deterioration is usually very slow if cells are properly stored. If unused cells are stored in a cool place, their shelf life will be greatly increased. Therefore, to minimize deterioration, battery cells should be stored in refrigerated spaces for best shelf life results.

The blotting paper used in dry cells serves two purposes:

- It keeps the paste from making actual contact with the zinc container, and

- It permits and allows the electrolyte from the paste to slowly filter through the paper to the zinc.

The cell is sealed at the top to keep air from entering and drying out the electrolyte paste. Care should be taken to prevent breaking this seal.

Mercury Cell

The mercuric-oxide zinc cell (mercury cell) is a primary cell that was first developed back during WWII. Two important aspects of the mercury cell are, its ability to produce current for a long period of time and a long shelf life when compared to the dry cell. The mercury cell also has a very stable output voltage and is a power source that can be made in a small physical size.

Mercury cells are small cells that can be easily manufactured that deliver maximum electrical energy at a constant and stable discharge voltage rate. There are several different types of mercury cells, such as the Wound Anode Flat, the Flat Pellet Structure, and the Cylindrical Structure types.

The wound-anode type has an anode composed of a corrugated zinc strip with a paper absorbent. The zinc is mixed with mercury, and the paper is soaked in the electrolyte which causes it to swell and press against the zinc and make positive contact. This process insures that the electrolyte makes contact with the anode.

In the pressed-powder cells the zinc powder for the anode is mixed prior to being pressed into shape. The absorbent is paper that is soaked in the electrolyte. The space between the inner and outer containers provides passage for any gas generated by an improper chemical balance or impurities present within the cell.

There are many different types of primary cells (manganese dioxide-alkaline-zinc-cells, magnesium-manganese dioxide cells, lithium-organic cells, lithium-inorganic cells, etc...), and they are developed differently for many reasons, including reasons such as cost, size, ease of replacement, voltage or current needs, etc..

The Lithium-Organic Cell and the Lithium-Inorganic Cell have a main advantages of producing very high power, operation over a wide temperature range, they are lighter than most cells, and they have a remarkably longer shelf life of up to 20 years.

Secondary Wet Cells

Secondary cells are sometimes known as wet cells. There are four basic type of wet cells:

- Lead-Acid,

- Nickel-Cadmium,

- Silver-Zinc, and

- Silver-Cadmium.

Lead-Acid

The lead-acid cell is the most widely used secondary cell. The previous explanation of the secondary cell as described above describes exactly the manner in which the lead-acid cell provides electrical power. The discharging and charging action presented in electrochemical action describes the lead-acid cell.

The lead-acid cell has an anode of lead peroxide, a cathode of sponge lead, and the electrolyte is a solution of sulfuric acid and water.

Nickel-Cadmium

The nickel-cadmium cell (NICAD) is far superior to the lead-acid cell. In comparison to lead-acid cells, these cells generally require less maintenance throughout their service life in regard to the adding of electrolyte of water.

The major difference between the nickel-cadmium cell and the lead-acid cell is the material used in the cathode, anode, and electrolyte. In the nickel-cadmium cell the cathode is cadmium hydroxide, the anode is nickel hydroxide, and the electrolyte is potassium hydroxide and water.

The nickel-cadmium and lead-acid cells have capacities that are comparable at normal discharge rates, but at high discharge rates the nickel-cadmium cell can deliver a larger amount of power. In addition the nickel-cadmium cell can:

- Be charged faster (in a shorter amount of time),

- Stay idle longer in any sate of charge and keep a full charge when stored for a longer period of time,

- And most importantly, be charged and discharged any number of times without any appreciable damage.

Silver-Zinc Cells

The silver-zinc cell is used extensively to power emergency equipment. This type of cell is relatively expensive and can be charged and discharged fewer times than other types of cells, before they obtain so much internal damage from the discharging process that they can no longer be recharged.

When compared to the lead-acid or nickel-cadmium cells these disadvantages are overcome by the light weight, small size, and good electrical capacity of the silver-zinc cell.

The silver-zinc cell uses the same electrolyte as the nickel0cadmium cell (that is, potassium hydroxide and water) but the anode is composed of silver oxide and the cathode is made of zinc.

Silver-Cadmium Cells

The silver-cadmium cell combines some of the better features of the nickel-cadmium and silver-zinc cells. It has more than twice the shelf life of the silver-zinc cell, and can be recharged many more times. However the disadvantages of the silver-cadmium cell are high cost and low voltage production.

The electrolyte of the silver-cadmium cell is potassium hydroxide and water. The anode is silver oxide, and the cathode is cadmium hydroxide. These combinations provide the cells with different qualities suitable for many varied applications.

Continue with Batteries - Part 2